The Ultimate Guide to e-PTFE Waterproof and Breathable Membranes: Unpacking the PTFE Raw Material

2025-11-04

If you’ve ever wondered how your favorite hiking jacket keeps you dry in a downpour while letting sweat escape, chances are an e-PTFE waterproof and breathable membrane is at work behind the scenes. This innovative material, derived from PTFE raw material, has revolutionized everything from outdoor gear to medical applications. In this guide, we’ll dive into what makes e-PTFE so special, exploring its characteristics, how it works, and why it’s a game-changer in various industries. Whether you’re a gear enthusiast or just curious about high-tech fabrics, stick around—I’ve got practical insights backed by solid science to help you understand and appreciate this “King of Plastics.”

What Is PTFE Raw Material and Why Does It Matter?

Let’s start at the basics. PTFE, or polytetrafluoroethylene, is a high-purity synthetic polymer made up of tetrafluoroethylene (TFE) units, often boasting a purity of 99% or higher. Known affectionately as Teflon in many circles—though that’s actually a brand name—PTFE raw material earns its “King of Plastics” title thanks to its unbeatable combination of properties. It’s incredibly inert, meaning it doesn’t react with most chemicals, solvents, or even strong acids and bases. This makes it perfect for harsh environments where other materials would break down.

From a physical standpoint, PTFE has a melting point around 327°C and can handle long-term working temperatures up to 288°C. It’s also non-toxic, UV-resistant, and has a super-low coefficient of friction, which is why it’s used in everything from non-stick cookware to industrial seals. But when we talk about e-PTFE, we’re referring to the expanded version of this raw material, stretched into a fine powder resin to create a membrane that’s both waterproof and breathable. Think of it as taking the toughness of PTFE and engineering it into a flexible, porous film that’s ideal for real-world use.

How e-PTFE Waterproof and Breathable Membranes Actually Work

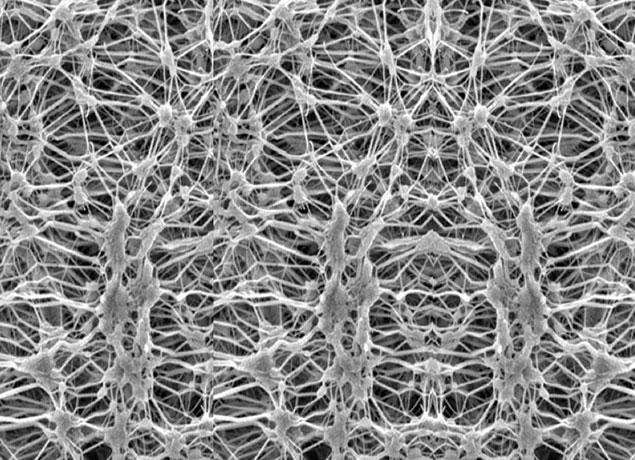

The magic of an e-PTFE waterproof and breathable membrane lies in its microstructure. By rapidly stretching the PTFE raw material, manufacturers create a uniform three-dimensional network of micropores, typically ranging from 0.1 to 10 micrometers in diameter. That’s tiny—about 250 to 25,000 times larger than a gas molecule (around 0.0004 μm), which means air and water vapor can pass through effortlessly. But for liquids like water droplets or dust particles? They’re way too big to squeeze in.

Here’s where surface tension comes into play: small water droplets condense into larger beads on the membrane’s surface, thanks to its extremely low surface energy (with a contact angle of about 135.6°). This repels water and oil, preventing penetration while allowing breathability. The result? You stay dry from the outside while moisture from sweat evaporates away. It’s this balance that makes e-PTFE stand out in waterproof breathable technologies.

To visualize this, check out these close-up views of the e-PTFE microstructure under a microscope. It’s like a web of tiny fibers creating billions of pores per square inch.

What really sets e-PTFE apart are its inherited traits from PTFE raw material, amplified for practical applications. Here’s a breakdown of the standout features:

- Chemical Resistance and Inertness: It withstands extreme temperatures, strong acids, alkalis, and most solvents without degrading. This makes it ideal for industrial filters or protective clothing in corrosive settings.

- Flame Retardancy and UV Resistance: e-PTFE doesn’t easily burn and holds up against sunlight, ensuring longevity in outdoor use.

- Hydrophobicity and Oil Repellency: With a surface tension of just 18.5 dyn/cm, it repels water and oils naturally, reducing the need for additional coatings.

- Low Friction and Non-Toxicity: Smooth and safe, it’s compliant for food contact and medical uses.

In harsh working environments, e-PTFE serves as a high-efficiency filtration medium, blocking contaminants while maintaining airflow. I’ve seen it in action in everything from air purifiers to protective vents in electronics—it’s versatile and reliable.

Applications in Outdoor Gear: Staying Dry and Comfortable on the Trail

One of the most common places you’ll encounter an e-PTFE waterproof and breathable membrane is in outdoor apparel. Brands like Gore-Tex use similar tech in jackets, pants, and shoes to provide windproof, waterproof protection without turning you into a sweatbox. For hikers or runners, this means you can push through rain or snow while your body heat escapes, preventing that clammy feeling.

Take a waterproof jacket, for example: the e-PTFE layer acts as a barrier against rain (up to high water entry pressures) but lets vapor out, enhancing comfort during intense activities. It’s also lightweight and durable, resisting tears and abrasion from backpacks or branches. If you’re gearing up for a multi-day trek, look for gear with e-PTFE—it’s worth the investment for that dry, breathable performance.

Here’s a glimpse of how it looks in real outdoor scenarios:

Benefits in Medical Applications: Protection Where It Counts

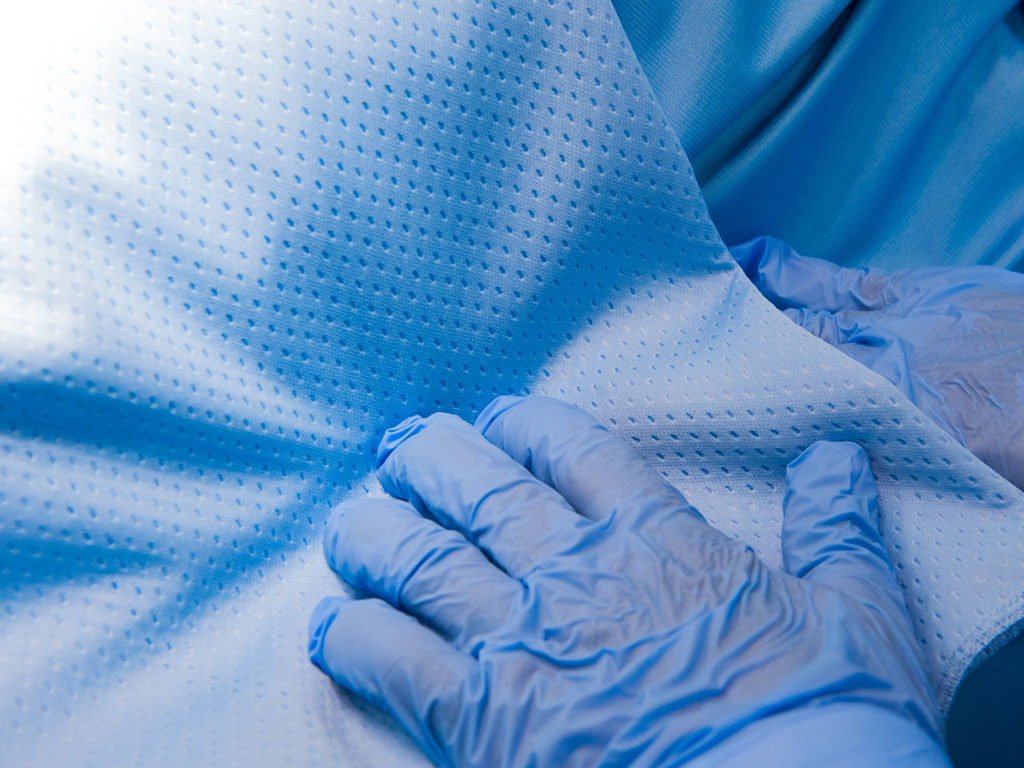

Beyond the trails, e-PTFE shines in healthcare. Its biocompatibility and barrier properties make it essential in surgical gowns, wound dressings, and even vascular grafts. For instance, in reusable surgical textiles, e-PTFE provides a shield against liquids and microbes while allowing air circulation, keeping surgeons comfortable during long procedures. It maintains waterproofing through multiple sterilizations and resists degradation, which is crucial in sterile environments.

In wound care, e-PTFE membranes promote healing by allowing gas exchange while blocking bacteria, reducing infection risks. It’s non-toxic and inert, so it doesn’t irritate skin or tissues. If you’re in the medical field, opting for e-PTFE-based products can mean better patient outcomes and longer-lasting equipment.

Visualize it in a clinical setting:

Why e-PTFE Is the Future of Waterproof Breathable Tech

Wrapping this up, the e-PTFE waterproof and breathable membrane, built from robust PTFE raw material, offers a unique blend of protection, durability, and comfort that’s hard to beat. Whether shielding electronics from dust, enhancing outdoor adventures, or safeguarding medical professionals, its microporous design delivers real-world benefits. If you’re shopping for gear or materials, prioritize e-PTFE for its proven track record in tough conditions—it’s not just hype; it’s engineering at its best. Have you tried products with this tech? Share your experiences in the comments!