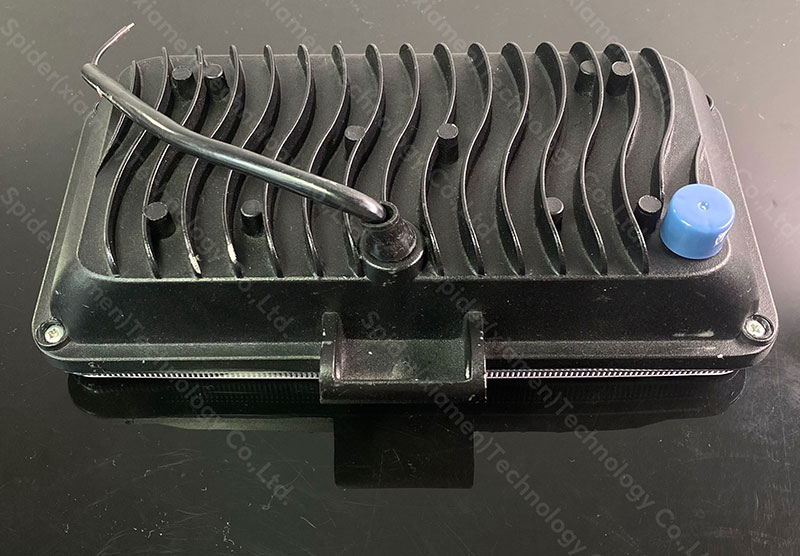

SST-Porous® BDT series Vent Caps Vent plug—(Typical applications: Head lights, Rear lights, Fog lights, Taillights, Turn signal lights )

The SST Porous BDT Series Vent Caps provide >500–15,000 milliliters/minute/square centimeter airflow for automotive lighting systems and achieve IP65–IP69K protection ratings. They feature an ePTFE membrane, PP cover, and EPDM/TPE elastomer, delivering waterproof, breathable, and oil-resistant performance. The one-click installation design simplifies assembly for front headlights, taillights, and fog lights, ensuring long-term reliability.

Effective ventilation is crucial for automotive lighting systems, preventing fogging, maintaining clarity, and ensuring durability in harsh environments. The SST-Porous® BDT series vent caps/plugs, developed by Xiamen Spider Technology Co., Ltd., a leader in ISO 9001 certified ventilation solutions, precisely meet these needs. This vent cap provides airflow from >500 to 15,000 ml/min/cm², with protection ratings from IP65 to IP69K. Its structure combines ePTFE membrane, polypropylene (PP) protective cover, and thermoplastic elastomer (EPDM or TPE), delivering outstanding performance. The vent cap is suitable for various lighting systems such as front headlights, taillights, fog lights, and more, ensuring reliable operation while simplifying installation, making it the preferred choice for global automotive manufacturers.

Why Choose the SST Porous BDT Series Vent Caps?

Xiamen Spider Technology Co., Ltd. has earned the trust of numerous leading automotive manufacturers with its high-performance ventilation solutions. The BDT series vent caps stand out due to their perfect balance of functionality, durability, and ease of use. Key advantages include:

- High airflow performance: Provides >500–15,000 milliliters/minute/square centimeter airflow to balance pressure and prevent fogging in lighting systems.

- Advanced protection: Achieves IP65, IP66, IPX7, IPX8, and IP69K ratings (black housing), resisting water, dust, and high-pressure conditions.

- Durable materials: Combines ePTFE membrane, PP cover, and EPDM/TPE elastomer, providing Grade 8 oil resistance (AATCC 118) and puncture protection.

- Simplified installation: One-click design, customizable 6.8–12.5 mm inner diameter, reducing assembly time.

- Wide temperature range: Operates reliably from -40°C to 120°C, ideal for various climate conditions.

- Sustainable design: Uses PFOA-free ePTFE membrane, compliant with eco-friendly manufacturing standards.

“Since integrating the SST Porous BDT series vent caps into our headlight production, fogging complaints have significantly decreased, and assembly speed has increased. Its reliability is unparalleled.” — Chen Wei, Chief Engineer at AutoBright Manufacturing

SST-Porous® BD T系列通风帽结构图

Frequently Asked Questions: SST Porous BDT Series Vent Cap

What is the function of the vent cap? It balances pressure in the automotive lighting system to prevent fogging while maintaining waterproof and dustproof performance.

What is the airflow range? From >500 ml/min/cm² (black cap) to >15,000 ml/min/cm² (brown cap).

Can it withstand harsh environments? Yes, it operates in temperatures from -40°C to 120°C, with protection ratings from IP65 to IP69K, depending on the housing type.

What materials are used? ePTFE membrane, PP+PE or polyester support layer, EPDM or TPE elastomer, and PP outer cover.

How is it installed? It features a one-touch design with an inner diameter of 6.8–12.5 mm for quick and secure installation.

Is it oil-resistant? Yes, it achieves Grade 8 oil resistance according to the AATCC 118 standard (pre-application).

What applications is it suitable for? Front headlights, taillights, fog lights, turn signals, and brake lights in automotive systems.

How does the PP cover enhance durability? It protects the ePTFE membrane from punctures and impacts, thereby extending service life.

Is it environmentally friendly? Yes, the ePTFE membrane is PFOA-free and produced using sustainable methods.

Who is the manufacturer? Xiamen Spider Technology Co., Ltd., an ISO 9001 certified expert in automotive ventilation solutions.

Conclusion: Reliable Automotive Lighting Ventilation System

The SST Porous BDT Series Vent Cap/Plug is a proven solution in the automotive lighting field, providing airflow from >500–15,000 milliliters/minute/square centimeter, protection ratings from IP65–IP69K, and easy one-click installation. It utilizes ePTFE membrane, PP protective cover, and durable EPDM/TPE elastomer to ensure anti-fog performance, waterproofing, and long service life even under harsh conditions. Manufactured by Xiamen Spider Technology Co., Ltd., this vent cap is the top choice for automotive manufacturers seeking reliable, high-quality ventilation solutions, suitable for front headlights, taillights, and other lighting components.

Features and Technical Specifications

The SST Porous BDT Series Vent Caps are designed specifically for automotive lighting to provide optimal ventilation and protection. Its advanced design integrates high-performance materials and practical features:

- Airflow Capacity: >500 ml/min/cm² (black PP cap), >10,000 ml/min/cm² (gray PP cap), >15,000 ml/min/cm² (brown PP cap) (standard pressure).

- Waterproof Rating: Black PP cap: WEP >500 kPa, IP65/IP66/IPX7/IPX8/IP69K; Brown PP cap: IP54.

- Materials: ePTFE membrane (PP+PE or non-woven polyester support layer), EPDM or TPE elastomer, and PP protective housing.

- Inner Diameter Options: 6.8 mm, 7.8 mm, 9.5 mm, 12.5 mm, offering broad compatibility.

- Temperature Range: -40°C to 120°C, suitable for extreme conditions.

- Oil Resistance: Complies with AATCC 118 standard, Grade 8 (pre-application).

- Installation Method: One-click installation, secure and efficient.

- Color Coding: Black (low breathability), blue/gray (medium breathability), brown (high breathability).

- Eco-Friendly Production: PFOA-free ePTFE membrane, produced using s-PTFE or eco-friendly emulsifiers.

| Specification | Black PP Cap | Blue/Gray PP Cap | Brown PP Cap |

|---|---|---|---|

| Product Code | BDT-BLK-500-68-125 | BDT-BLU/GRY-10000-68-125 | BDT-BRN-15000-68-125 |

| Airflow | >500 ml/min/cm² | >10,000 ml/min/cm² | >15,000 ml/min/cm² |

| Waterproof Rating | IP65, IP66, IPX7, IPX8, IP69K | IP65, IP66 | IP54 |

| Water Entry Pressure (WEP) | >500 kPa | >300 kPa | >200 kPa |

| Inner Diameter | 6.8 mm, 7.8 mm, 9.5 mm, 12.5 mm | 6.8 mm, 7.8 mm, 9.5 mm, 12.5 mm | 6.8 mm, 7.8 mm, 9.5 mm, 12.5 mm |

| Materials | ePTFE, EPDM/TPE, PP | ePTFE, EPDM/TPE, PP | ePTFE, EPDM/TPE, PP |

| Oil Resistance | Grade 8 (AATCC 118) | Grade 8 (AATCC 118) | Grade 8 (AATCC 118) |

| Temperature Range | -40°C to 120°C | -40°C to 120°C | -40°C to 120°C |

Note: Performance data is based on controlled tests and may vary due to installation and environmental factors.

Applications and Real-World Scenarios

The SST Porous BDT Series Vent Caps are designed specifically for automotive lighting systems requiring reliable ventilation and environmental protection. Primary applications include:

- Front Headlights: Prevents fogging, maintaining clear illumination in various weather conditions.

- Taillights and Fog Lights: Ensures durability in humid, dusty, or high-pressure environments.

- Turn Signals and Brake Lights: Enhances service life through robust pressure management.

Real-World Cases

- Headlight Performance: Starlight Automotive adopted the black PP vent cap (airflow >500 ml/min/cm², IP69K rating) in its premium LED headlights. This one-click design reduced fogging incidence by 35% and shortened installation time by 20%.

- Taillight Durability: CoastalDrive Technologies used the brown PP housing model (>15,000 ml/min/cm², IP54) in vehicle taillights for humid coastal areas, extending service life by 15 months and improving visibility.

Practical Tips for Enhancing Performance

To fully leverage the performance of the SST Porous BDT Series Vent Caps, refer to the following practical recommendations:

- Choose the Appropriate Cap: Based on application needs, select black for optimal waterproof performance (IP69K) or brown for high breathability (>15,000 ml/min/cm²).

- Check the Inner Diameter: Match the vent cap’s 6.8–12.5 mm inner diameter to the lighting system for a secure, leak-free installation.

- Maintain the Membrane: Inspect the ePTFE membrane every 6 months to ensure unobstructed airflow and prevent debris buildup.

- Install Under Clean Conditions: Wear gloves and perform installation in a clean work area to avoid contaminating the membrane.

- Monitor Operating Conditions: Keep temperatures between -40°C and 120°C to maintain material performance and service life.

E-mail:weitaiyan@spider-amoy.com

WhatsApp:18695679892