SST-Porous®Weldable Membrane Vents& BD01 series -(typical application:Sensors, ECU, Automotive electronic components, Electric toothbrush, Tooth puncher, Razor, Sweeping robot,Robot mower, etc)

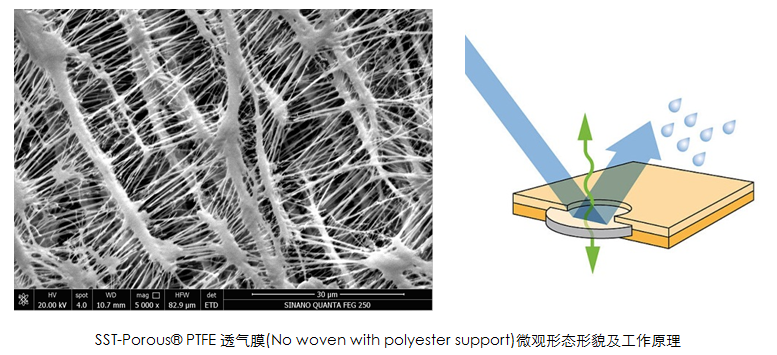

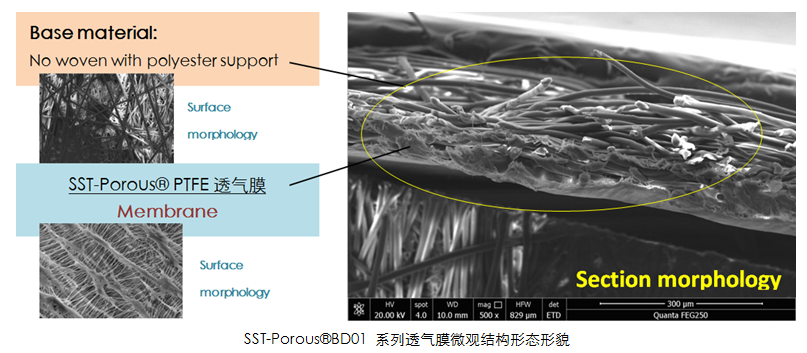

SST-Porous ® BD 01 series Weldable protective vents products, made by SST porous ® e-PTFE membrane and polyester non-woven fabric are thermally compounded, and then the membrane are integrated with target components through hot-melt or ultrasonic welding process.

What is SST-Porous®Weldable Membrane Vent&BD01 series Protective vents?

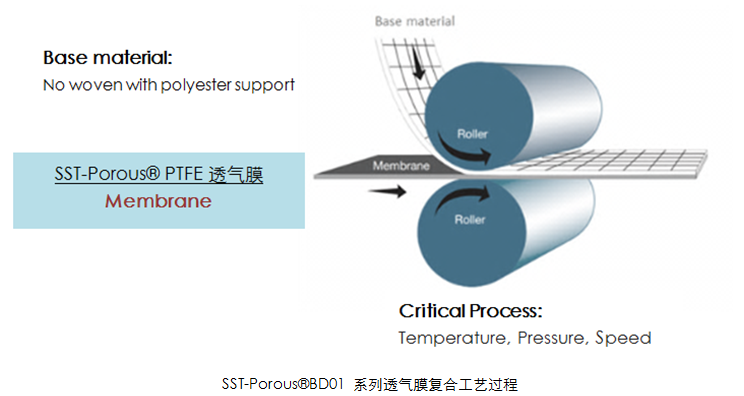

SST-Porous®BD 01 series weldable protection vents, R&D by Spider (SST) independently, made of SST-Porous® PTFE permeable membrane combined with base material no-woven with polyester through hot-pressing device under specific temperatures, pressures and speeds. This laminated permeable membrane still maintains a high permeability and average pore diameter, and is not easily be layered.

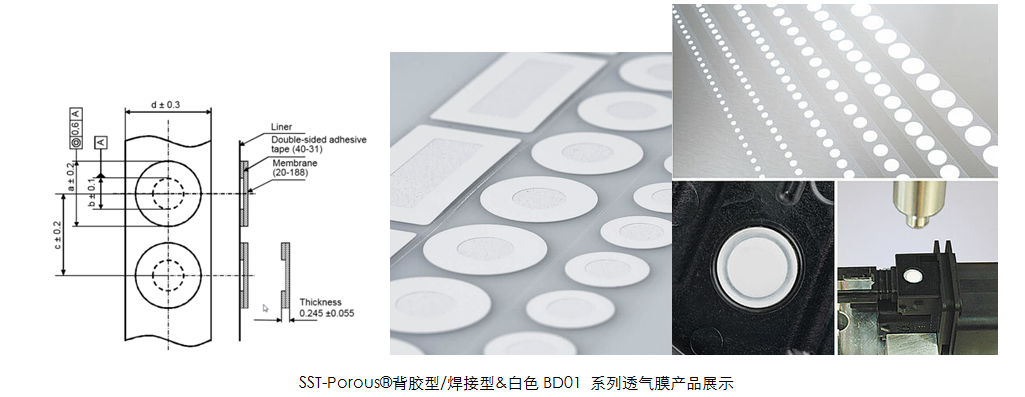

SST-Porous® BD01 series membrane, combined with acrylic double-sided adhesive that comes adhesive protection vents. If not do the adhesive process, the protection vents could be welded with housing(PP,PBT,ABS,PC,PA6 etc) by ultrasonic or thermal melt.

SST-Porous® weldable & white color BD01 series protection vents, having the function of waterproof、pemeablility, dustproof and equalization inside pressure(compensation pressure), could be installed to the electronic housing semi-automatically or manually.

SST-Porous®Weldable & BD01 series Protection vents Processing:

SST-Porous® PTFE breather membrane, through precision die cutting process, die cutting adhesive size according to the actual working conditions or customer specifications, made into SST bulk breather protection vent for delivery.

SST-Porous@weldable Weldable Membrane Vents &while color BD01 series protection vents’s features and characteristic:

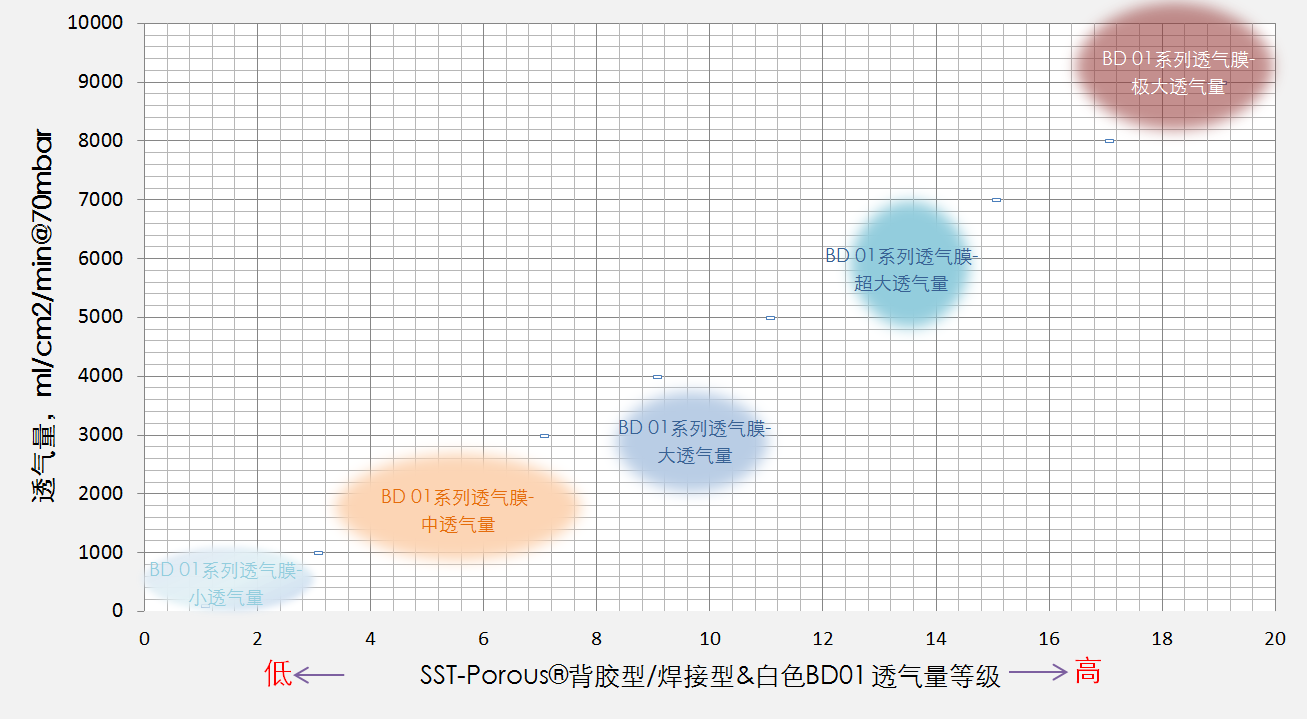

1 Breathability

SST-Porous®Weldable & white color BD01 series pemeable protection vents,formed by SST-Porous® pemeable membrane and none-woven polyester through hot-pressing process, with excellent airflow.

|

|

BD 01 series

Low Airflow |

BD 01 series

Medium Airflow |

BD 01 series

High Airflow |

BD 01 series

Super High Airflow |

| Typical Airflow | > 500 | 1000~2000 | 2500~3000 |

5000以上 |

|

Attention: ※ Airflow test is measured for the membrane vents before usage,unit:ml/min/cm2 ※ at ΔP = 70 mbar, RT |

||||

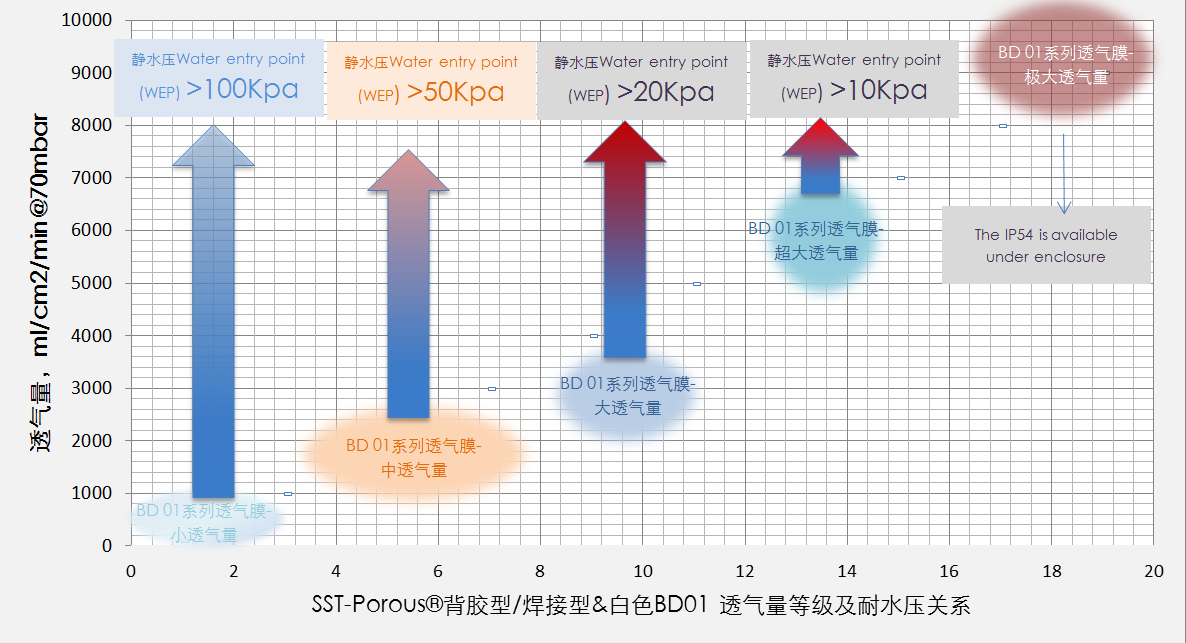

2 Waterproof

SST-Porous®weldable& BD01 series, as SST-Porous® pemeable membrane’s special structure of “fiber” and “node” network, the protection vents not only with excellent airflow performance but outstanding water resistance.

|

|

BD 01 series

Low Airflow |

BD 01 series

Medium Airflow |

BD 01 series

High Airflow |

BD 01 series

Super High Airflow |

|

Water entry point (WEP) |

> 100 | > 50 | > 20 |

> 10 |

| Ingress Protection

(IP) |

IP54、IP65/ IP66、IPX7、IPX8、IP69K | IP54、IP65/ IP66、IPX7、IPX8 | IP54、IP65/ IP66、IPX7 |

IP54、IP65/ IP66、IPX7 |

|

Attention: ※ WEP @kPa@ Dynamic WEP 30 sec, RT, ※ Protection against foreign particles, water, and touching according to ISO 20653:2013 |

||||

3 Hydropobic & Oleophobic

SST-Porous® could supply hydrophobic and Oleophobic to meet different application requirement. As it’s Oleophobic characteristic, the protection vent could maintaining airflow even after contact with high-viscous or low surface-tension liquids.

※ BD 01 serial characteristic (Before Application):

Oleophobic rate from 1 to 8 (according to AATCC 118)

4 Weldability

SST-Porous®BD 01 series(no adhesive), The protection venting could be installed to the plastic housing by means of thermal melt or ultrasonic welding.

-

A common type of plastic that could be welded

ABS,PBT,PP,HDPE,PA6,PC etc.

- Temperature of thermal welding

The temperature mainly depends on the melting point (Tm) of the plastic, generally 30~50℃ higher than selected plastic TM can be smoothly welded.

5 High adhesive strength

SST-Porous®BD BD01 series Adhesive venting in white color, the designed double-sided adhesive, in addition to its good adhesive with low surface PTFE , but also take into account the viscosity of the surface with different materials.

※ Adhesion Properties of Adhesive

Adhesive strength according to FINAT FTM 1, RT Steel (after 24 h) : > 19 N/25 mm

6 Withstanding low and high temperature

Continuous Operating Temperature Range: -40 °C to +130 °C (when adhered)

Explanation:

- the venting usage temperature mainly depends on the temperature of adhesive or the venting base material;

- if special temperature required, SST could supply adhesive venting with more wider range of temeprature.

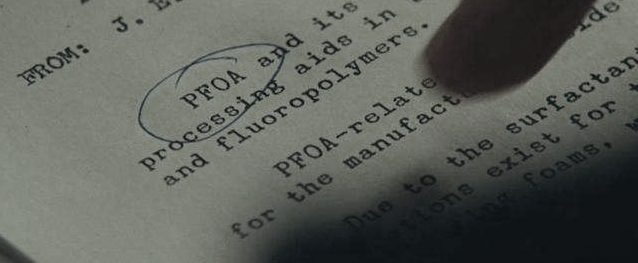

7 None-PFOA

SST-Porous®s-PTFE adhesive/weldable & white color BD 01 serial, the membrane used is different from e-PTFE material of PTEF, it’s obtained from suspension liquid, no need emulgator PFOA (PFOA suspected having carcinogenic effects), so SST-Porous® s-PTFE adhesive/weldable & white color BD 01 serial don’t have PFOA.

And, if specified SST-Porous® e-PTFE adhesive/weldable @ white color BD 01 series protective vents, we could choose eco-friendly emulgator prepared by PTFE dispersion raw materials, thus, SST-Porous® waterproof & breathable vents do not contain PFOA.

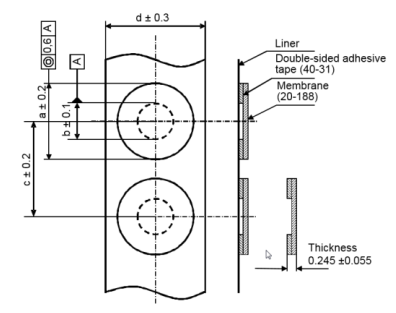

8 Customizability

SST-Porous®BD 01 series Adhesive/Weldable protection vent in white color, the double-sided adhesive composition, package method, size, and shape could be customized.

|

※(OD)&(ID)sizes OD : 2~30 mm ID: 1~28 mm

Attention: SST could produce the adhesive venting according to customer drawing or sample. |

※Supply mode

|

Supply mode |

Description |

|

By sheet |

50~150pcs/sheet |

| By roll in single row |

50~100m/roll |

| By roll in multi-row |

50~100m/roll |

typical application

- Sensors

- ECU

- Automotive electronic components

- Electric toothbrush

- Tooth puncher

- Razor

- Sweeping robot

- Robot mower

Processing Guidelines/Installation Recommendations

SST Welding type vent are high-tech products requiring professional post-processing. Please get intouch with us when planning your manufacturing process. Not all post-processing systems are compatible with this product. We will be pleased to provide you with our know-how and expertise in the field.

Processing instructions

- When handling the SST Welding type vent, be sure to use blunt tweezers to clamp the vents;

- The surface of the installed plastic shell shall be kept clean and free of oil, particles and other pollutants;

- When using the automatic installation machine, Welding type vent shall be made into coiled materials (strip or die cut coiled materials);

- For the manually installed SST Welding type vent, attention should be paid to the selection of the welding surface (generally the base material surface is welded with the plastic shell);

E-mail:weitaiyan@spider-amoy.com

WhatsApp:18695679892