Automotive Microphone Acoustic Vent Membrane: Enhancing Environmental Resilience in Vehicle Acoustic Systems

2025-12-01

Introduction

The acceleration of vehicle intelligence has positioned automotive microphones as pivotal components in voice interaction, noise cancellation, and driver assistance systems. These elements must contend with environmental stressors such as dust, humidity fluctuations, and liquid exposure. e-PTFE-based waterproof acoustic vent membranes achieve a balance between acoustic signal transmission and protection through microporous structures, making them suitable for integration in automotive microphones. This article examines the technical considerations and compliance pathways for automotive microphone acoustic vent membranes in vehicle applications, drawing on international standards data.

Regulatory Background

The International Electrotechnical Commission (IEC) standard IEC 60529:2020 defines the Ingress Protection (IP) code, where IP67 mandates complete dust protection and submersion in 1 meter of water for 30 minutes, simulating automotive wading or rain scenarios. This standard applies to enclosure assessments, ensuring automotive microphones maintain functionality under liquid contact.

SAE International’s J1455:2017 Recommended Practice establishes environmental testing guidelines for heavy-duty vehicle electronics, encompassing salt fog exposure, rain spray, and immersion tests across a -40°C to 85°C temperature range. These protocols validate the sealing efficacy of waterproof acoustic vent membranes in corrosive media.

The European Chemicals Agency (ECHA) released an update to the REACH regulation’s PFAS restriction proposal on August 20, 2025, introducing bans and limits on materials like automotive coatings to reduce environmental emissions and promote PFAS-free alternatives. The proposal addresses over 10,000 PFAS uses, impacting compliance in automotive waterproof material supply chains.

Industry Challenges

Automotive microphones are susceptible to dust ingress and liquid penetration, resulting in signal distortion and component corrosion. SAE J1455:2017 highlights how environmental factors like salt fog and rain exposure can substantially degrade electronic reliability, particularly in heavy-duty vehicle applications. Under road conditions with dust concentrations exceeding 50 mg/m³, ingress tests indicate that sealing defects amplify failure risks.

IEC 60529 testing reveals that under high-pressure water jet conditions (IPX9K), microphone enclosure water ingress rates can reach 10-20%, disrupting voice capture and introducing noise. Such failures are especially pronounced in electric vehicle ADAS voice interfaces, escalating maintenance requirements.

ECHA’s 2025 PFAS usage mapping report notes that PFAS applications in the automotive sector represent a significant portion of registered substances, with persistent pollutants contributing to soil and water accumulation, thereby intensifying supply chain environmental pressures.

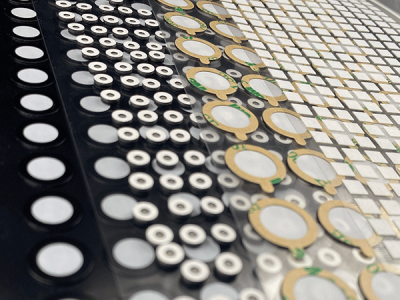

SST Product Advantages and Solutions

The SST-Porous® AV-00 series automotive microphone acoustic vent membrane employs an e-PTFE substrate-free design with a thickness of 10-100 μm, achieving ≤2 dB sound loss at 1 kHz while supporting IPX7/IPX8 waterproofing (30 minutes at 2.5 meters water depth). Air permeability reaches 10,000 ml/cm²/min at 70 mbar to balance internal and external pressures, with hydrostatic head resistance of 30-500 kPa (50 seconds) aligning with SAE J1455 immersion requirements.

Oleophobic surface treatment blocks 1-10 μm particles, reducing acoustic attenuation by 20% and sustaining high sound pressure level transmission. Materials are PFOA-free, compliant with RoHS and REACH, addressing ECHA’s PFAS proposal.

Why Choose SST

Spider(Xiamen) Technology Co., Ltd was established in 2016, specializing in e-PTFE membranes and protective venting products for over a decade. Protection levels reach IP67/IP68/IP69K, with certifications including ISO9001 and IATF16949, alongside third-party reports from SGS, UL, RoHS, and REACH.

SST facilitates customization from membrane thickness to dimensions (OD 5 mm/ID 2 mm), verified against IEC 60529 and SAE J1455 for integration compatibility.

SST Industry Applications

SST automotive microphone acoustic vent membranes are applicable to Advanced Driver Assistance Systems (ADAS) voice modules, in-cabin entertainment systems, and hands-free communication devices. These application domains span the full lifecycle from concept validation to mass production, encompassing environmental simulation testing in prototypes and sealing integration in final assembly.

Verification phases adhere to the International Electrotechnical Commission (IEC) standard IEC 60529 for Ingress Protection (IP) testing protocols, as well as SAE International J1455 Recommended Practice for durability assessments, including salt fog exposure, rain spray, and immersion tests to validate electronic device performance within a -40°C to 85°C temperature range. These tests ensure the vent membrane maintains acoustic transmission performance in corrosive environments, extending microphone service life.

Standards compliance encompasses IP69K-level resistance to high-pressure, high-temperature water jets for extreme cleaning conditions in automotive electronics, along with REACH regulation declarations of no per- and polyfluoroalkyl substances (PFAS), supporting the European Chemicals Agency (ECHA) 2025 PFAS restriction proposal for automotive materials. This compliance aids automotive Original Equipment Manufacturers (OEMs) in achieving reliable global market deployment.

SST’s Mission, Values, and Innovation Commitment

Spider(Xiamen) Technology Co., Ltd upholds the core philosophy of “Integrity Forges Quality, Innovation Leads the Future,” consistently balancing economic benefits with social responsibility, actively fulfilling environmental protection obligations, and promoting harmonious coexistence between humanity and nature. The company features a research and development team of master’s and doctoral-level polymer materials experts, allocating 5-20% of annual revenue to new product development.

We invite you to contact us at weitaiyan@spider-amoy.com to discuss customized solutions for automotive microphone acoustic vent membranes.