IPX8 Compliance in Smartwatch Design: Immersion Protection Acoustic Membrane Solutions

2025-12-15

Introduction

Smartwatches have evolved into essential tools for health monitoring and fitness tracking, with global shipments projected to reach 230.11 million units in 2025. As consumers demand devices that withstand immersion during swimming or diving, engineers must integrate deep waterproofing without compromising acoustic performance. Expanded polytetrafluoroethylene (ePTFE) acoustic venting membranes address this challenge by enabling pressure equalization and sound transmission while blocking water ingress. This article explores the regulatory framework, waterproofing pain points, and material solutions based on standards such as IEC 60529.

Regulatory Background

International standards define waterproof ratings for consumer electronics, ensuring devices like smartwatches operate reliably in humid environments. The IEC 60529 standard classifies Ingress Protection (IP) ratings, where IPX8 specifies continuous immersion beyond 1 meter in depth, with duration and conditions set by the manufacturer—typically at least 1 meter deep for 30 minutes. For wearable devices, this translates to a 50-meter depth immersion test for 10 minutes under IP68, as demonstrated by IEC 60529:2013 certified equipment.

Chemical regulations further impact membrane materials. The European Chemicals Agency (ECHA) restricts per- and polyfluoroalkyl substances (PFAS) in waterproof fluoropolymers, including perfluorooctanoic acid (PFOA), prohibiting concentrations exceeding 25 parts per billion in articles since 2020. ECHA’s January 2023 update proposal aims to extend these restrictions to all PFAS, targeting emissions from PFAS polymers such as ePTFE, with annual European production ranging from 84,000 to 199,000 tons. Compliance requires PFOA-free formulations to meet REACH requirements.

While SAE standards like J1455 emphasize vibration, thermal cycling, and humidity resistance for automotive electronics environmental testing, for non-vehicle wearables, the core waterproofing metrics align with IEC standards.

Industry Pain Points

Water exposure remains a primary cause of smartwatch failures, accounting for 28% of incidents and resulting in global annual repair costs of $450 million. Data from 2020 indicates that water ingress causes 15% of failures, often manifesting as screen fogging or sensor malfunctions after immersion.

Acoustic components exacerbate these risks. Microphones and speakers in smartwatches require venting for sound transmission, but traditional seals fail under hydrostatic pressure, leading to a 20-30% drop in audio clarity after IPX8 exposure. Dust particles below 10 μm, common in urban or outdoor environments, further clog vents, reducing airflow permeability by up to 50% over time and causing internal pressure imbalances that stress the enclosure.

Market dynamics amplify these challenges: The smartwatch industry is projected to grow from $64.46 billion in 2025 to $229.46 billion by 2033, at a compound annual growth rate of 17.2%, driven by health features. However, independent testing shows that only 40% of devices achieve verified IPX8 performance in real-world immersion, due to variations in membrane durability.

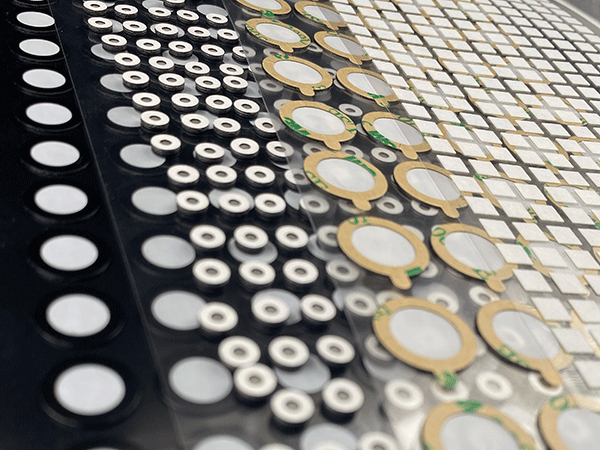

SST Product Advantages and Solutions

The SST-Porous® AV-00 series membranes utilize substrate-free ePTFE for acoustic protection in smartwatches, achieving IPX8 compliance up to 50 meters for 1 minute while limiting sound loss to ≤3 dB at 1 kHz. These membranes maintain an air permeability of 150 ml/cm²/min under 70 mbar pressure, enabling pressure equalization without water penetration, as verified by IEC 60529 protocols.

Compared to non-porous seals, the ePTFE structure provides an oleophobic surface that repels oils and particles below 1 μm, reducing clogging risks. Thickness options from 10 μm to 250 μm support integration for microphones (Mic) or speakers (Spk), withstanding 30-500 kPa water pressure for 50 seconds. All formulations are PFOA-free, compliant with ECHA restrictions.

Deployment involves laminating the membrane’s adhesive layer onto device vents, preserving original acoustic properties while enhancing overall enclosure integrity.

Why Choose SST

Spider (Xiamen) Technology Co., Ltd, founded in 2016, has specialized in ePTFE membranes and protective venting products for over nine years. Our solutions achieve protection ratings up to IP67, IP68, and IP69K, supporting immersion and high-pressure washdown applications.

We hold ISO 9001 and IATF 16949 certifications for quality management and automotive production standards. Independent validations include SGS material integrity testing, CE EU conformity marking, UL safety recognition, and RoHS and REACH compliance reports confirming PFOA-free status. These third-party assessments ensure supply chain traceability and reliability.

SST Industry Applications

The SST-Porous® AV-00 series is applied to smartwatch vents and acoustic ports, enhancing breathability in fitness trackers and dive-grade models. In validation phases, prototypes undergo IEC 60529 IPX8 immersion at specified depths, followed by acoustic benchmarking to confirm attenuation <3 dB across 20 Hz-20 kHz frequencies.

Compliance extends to ECHA PFAS guidelines, with REACH dossiers verifying low-emission characteristics. In ISO 20653 pressure equalization testing (applicable to wearables), the membranes withstand 5 ATM differential pressure without delamination, supporting ASTM F1670 microbial barrier integrity standards.

SST’s Mission, Values, and Innovation Commitment

Spider (Xiamen) Technology Co., Ltd upholds the core philosophy of “Integrity Forges Quality, Innovation Leads the Future.” We balance economic benefits with social responsibility, actively fulfilling environmental obligations to promote harmony between humanity and nature.

Our polymer materials R&D team, composed of master’s and PhD-level experts, invests 5-20% of annual revenue into new product development, continuously advancing ePTFE formulations for improved waterproofing performance.

For discussions on integrating SST solutions into your smartwatch designs, please contact us at info@spider-amoy.com.