> SST-Porous®MEMS Microphone transmission(Typical application:circuit board、Sisonic、MEMS microphone)

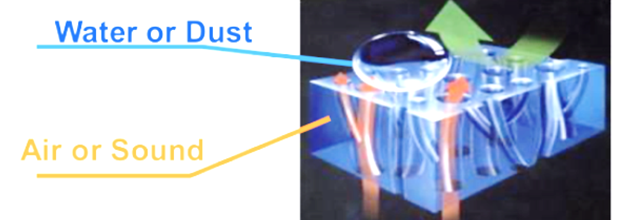

SST-Porous®MEMS microphone Acoustic vent protects the microphone from particle contamination and pressure buildup during reflow soldering, while at the same time making it possible to conduct in-process acoustic testing.

Summy

During the mass assembly of printed circuit boards for smartphones, video cameras and other consumer electronics devices, technical issues could compromise the integrity of the MEMS microphones. SST MEMS microphone permeable products effectively prevent particle contamination and pressure buildup, while enabling in-process acoustic performance testing and seamless matching to high-speed production lines.

What is SST-porous ®MEMS microphone Acoustic product

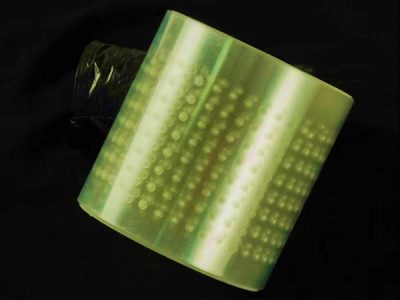

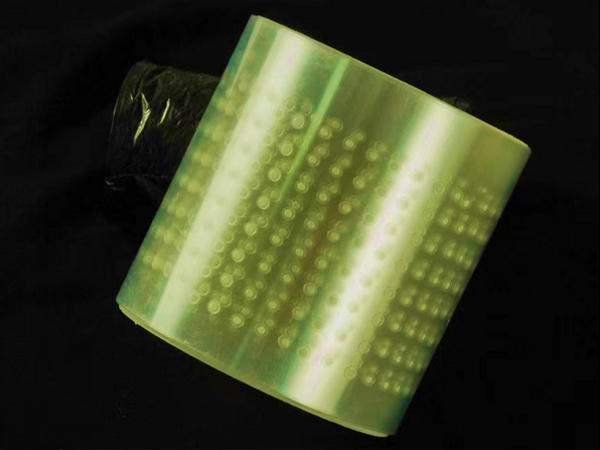

SST-Porous®MEMS microphone sound transmittance product is a PTFE porous membrane made by SST through a special process. This PTFE porous membrane is composed of thousands of microholes by “node” and “fiber”. It is the existence of this microhole that makes SST MEMS microphone sound transmittance membrane not only has excellent sound transmittance effect, but also makes the pressure release quickly in the reflow welding process. Better protect the safety and reliability of sensitive acoustic products. Because PTFE can be used for a long time at 260℃, it also better meet the high temperature drying channel, the durability of the product can be guaranteed.

|

|

Key features:1)Quickly balancing pressure prevents pressure buildup2)Perfect Sound penetration3)Effectively prevent particle contamnation |

产品特性特征

SST-Porous®MEMS麦克风透声产品能够保证敏感的声学元件在回流焊过程中,保持完整性,同时,保持优异的声学效果。

主要功能 |

硅麦回流焊过程保护,防止压力聚集 |

|

声音损耗@1kHz |

≤1dB |

|

透声膜类别 |

e-PTFE(无基材) |

|

颜色 |

白色 |

|

透气量, ml/cm2/min@70mbar |

10000 |

|

透声膜厚度,μm |

5 |

|

透声膜表面特性 |

疏水 |

|

过程保护过滤效果 |

>99.0% |

| 环保 |

符合Rohs, Reach要求 |

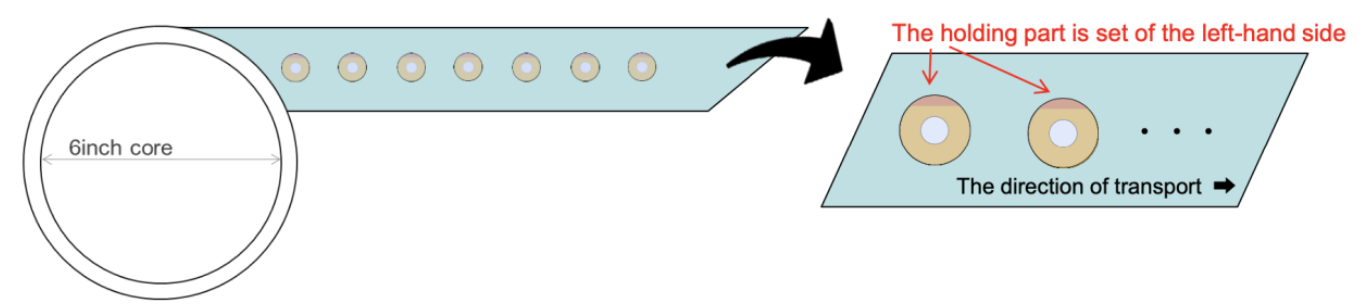

产品结构特征

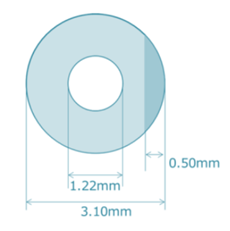

典型的规格尺寸 |

产品技术要求 |

|

ePTFE透声膜:满足耐高温(260℃10min)、大透气量及优异的声学效果 双面胶:采用耐高温双面胶(260℃10min) 支撑材料:耐高温PI作为增强材料 |

产品选择形式

适用于电路板组件

-

1)可安装在上出声孔麦克风顶部或下出声孔麦克风背面的电路板上

-

2)卷轴式包装

-

3)可无缝匹配高速SMT贴片机生产线

适用于麦克风制造商

-

1)可于麦克风封装过程中安装到MEMS麦克风内部

-

2)产品以类晶圆格式进行数字映射

-

3)与高速固晶设备兼容

产品应用

- 智能手机

- 运动摄像头

- 对讲机

- 智能手表

- 智能穿戴设备

- 蓝牙耳机

- 智能家居设备

- 智能音响

E-mail:weitaiyan@spider-amoy.com

WhatsApp:18695679892