How to protect ECU system of new energy vehicles?

2023-07-24

一、概述overview

With the continuous acceleration of the transformation of the automotive industry to electrification, and the variability and complexity of the environment in which electric vehicles are used, the protection requirements for the functional safety and reliability of electric vehicle components are also increasing. Automotive electronic components are susceptible to harsh environmental conditions. Whether installed under the vehicle chassis or in the engine compartment, electronic components such as those in electric motors, control units (ECUs), sensors, compressors or pumps are subject to extreme temperature fluctuations and must therefore be protected against the ingress of water, hazardous automotive fluids and particles that can damage electronic components.

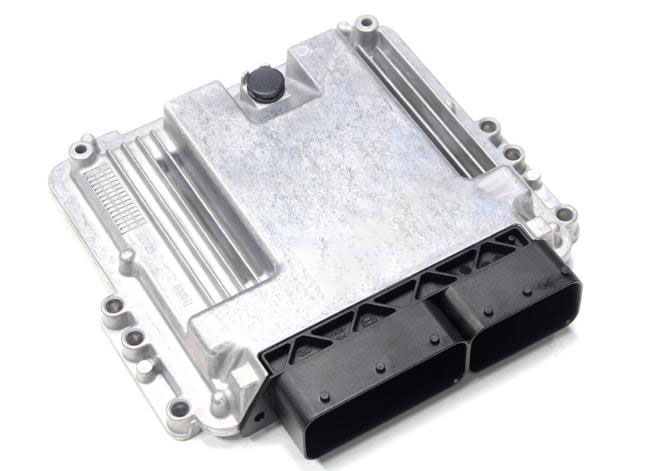

二、What is an Automotive Electronic Control Unit (ECU)

The electronic control unit (ECU) is the comprehensive control device of the engine. Its function is to calculate, process, and judge various information input by the various sensors of the engine according to the program stored in itself, and then output instructions to control the action of the relevant actuators, so as to achieve the purpose of fast, accurate, and automatic control of the engine.

三、Industry Pain Points

In the new energy vehicle industry, electronically controlled ECU systems face many challenges and pain points. For example, heat dissipation problems in high temperature environments, waterproof requirements in humid environments, etc. These problems have brought certain risks to the normal work of the electronic control system. Therefore, we need to find a solution that can solve the heat dissipation and waterproof problems at the same time.

四、The solution provided by SST

The solution provided by SST is a component composed of e-PTFE vent membrane and designed metal/plastic (aluminum alloy/stainless steel/nylon plastic, etc.) materials, which are welded by thermal fusion or ultrasonic, and the PTFE porous material is protected by a plastic cover. Effective waterproof and breathable functions can be achieved. The valve has high pressure resistance and temperature resistance, and can work stably in harsh environments. Its principle is to realize the permeation of gas molecules through the microporous membrane, and at the same time block the entry of liquid and solid particles, so as to achieve waterproof and breathable effects, and prevent it from being punctured, collided, etc., improve life, and product safety, reliability and durability.

五、Our products

1、welded vent membrane

SST-Porous® welded BD01 series ventilation products are made of SST-Porous® waterproof vent membrane and polyester non-woven fabric through thermal lamination, and then the vent membrane product is integrated into the target component through thermal fusion or ultrasonic welding.

2、snap-fit venting valve

The SST-Porous® plastic snap-fit venting valve product is independently developed by SST. It is composed of SST-Porous® PTFE vent membrane and PBT plastic injection molded parts, which are welded by thermal fusion or ultrasonic welding. The PTFE porous material is protected by the PBT upper cover, which can prevent it from being punctured, collided, etc., improve life, and product safety, reliability and durability. The entire component composed produces new functions and characteristics, reduces costs, and can realize one-click installation.