SST PORUS ® Vents Welding Product Manual

2023-09-14

Ⅰ、How welding works with SST POROUS® Vents

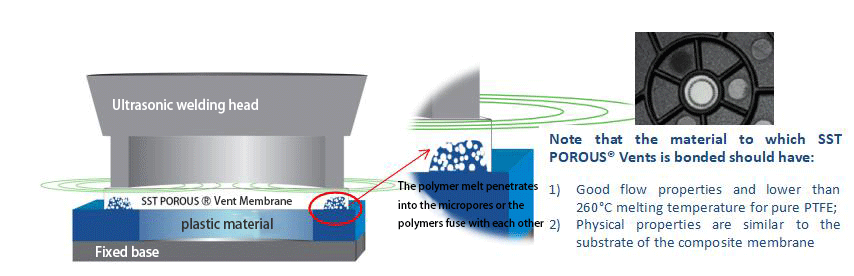

1.How Ultrasonically Weld works

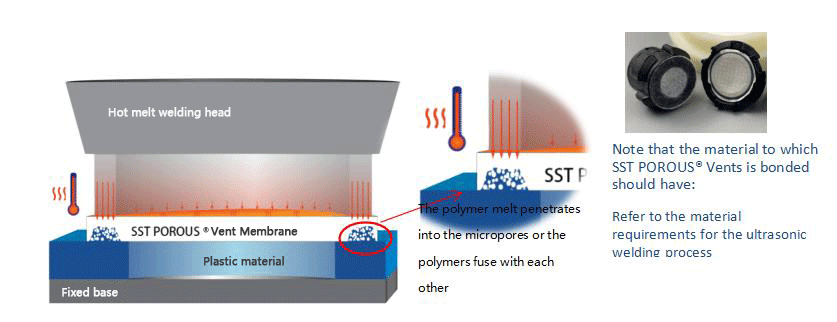

2.How hot melt weld works

Ⅱ、How to get started with welding SST POROUS® vents

1.Welding SST POROUS® vents type

|

①.Welding SST POROUS® vents with substrate |

Instruction |

|

|

|

|

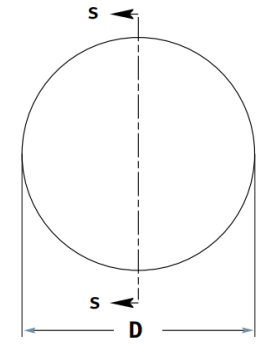

D = OD; Y = (e-PTFE) vents membrane; Z = Substrate; b = Typical thickness Tolerance: +/- 0.25mm

Welding surface recommendation: ⅰ.Welding SST POROUS® vents with substrate: Hot melt or ultrasonic welding with the target plastic housing by the z (support material) surface

ⅱ.100% welding SST POROUS® vents does not distinguish both sides

Note: Different plastic materials need to choose different types of support materials, available for technical solution www.spider-amoy.com through SST sales engineer |

|

②.Welding SST POROUS® vents with 100%PTFE |

||

|

|

|

|

2.Welding SST POROUS® vents typical physical properties parameters

|

\ |

Test Standard |

BDW00 series |

BD01 series |

BD06 series |

|

Structure |

\ |

100% PTFE membrane vents |

Welding SST POROUS® vents with substrate |

|

|

IP grade |

GB 4208-2008/ICE 60529-2001 |

IPX7/IPX8 |

||

|

Water entry pressure |

\ |

≥ 10kPa |

||

|

Typical air permeability |

Industry Standard |

100~10000ml/cm2/min@70mbar |

||

|

Operation Temperature |

GB/T2423.1-2008 |

Tmin = −40℃; Tmax = +160℃ |

Tmin =−40℃ ;Tmax = +125℃ |

|

|

Surface Properties |

(AATCC)118-1989 |

Oleophobic modification can be carried out according to the actual |

||

|

Category |

\ |

100% e-PTFE |

e-PTFE∣PET |

e-PTFE∣PP/PE |

|

Thickness,mm |

GB 6672-86 |

0.18±0.05 |

\ |

|

|

Notes |

※ The IPx7 resist the effects of soaking for 30 minutes in water up to 1meter deep ※ The IPx8 is usually agreed testing with the end user ※ The test area is 1cm2, and the test time is 50sec ※ The actual test air flow with a test area of 1cm2 application |

|||