SST Porous waterproof and breathable product category

2023-08-22

Ⅰ、 Explosion-proof valve

1.Overview

A properly designed venting system provides protection from contaminants and maintains pressure equalization under normal operating conditions, helping to achieve longer-lasting housing and battery life cycles. In the rare event of thermal runaway, the vent must also be able to relieve pressure immediately, helping to avoid component failure or damage to other units.

To meet this challenge, we have developed the SST-Porous® pressure relief valve. The PTFE pressure relief membrane in the component is able to compensate for the pressure difference, and at the same time can prevent water, dust, dirt and even engine oil from entering. They made the development of the degasser only to protect the high voltage battery from heavy rain or temporary immersion, but this can even stop water pressure cleaners sprayed by the high voltage battery.

2. Characteristic

1).Safety SST-Porous® pressure relief membrane allows emergency quick release of gas, quick release of pressure inside the Pack

2).Effectively reduce the condensation of the battery pack and prevent condensation from causing short circuits and corrosion inside the casing

3).Extend the service life of the system – continuous pressure compensation in the shell (waterproof, breathable and dustproof), and at the same time meet the protection level of IPX7, IP65

3.Application

1).Photovoltaic and wind power generation and power storage;

2).Automobile power, battery power storage

Ⅱ、Threaded vent valve (metal and plastic)

1.Overview

The SST-Porous® threaded vent valve product is independently developed by SST. It consists of SST-Porous® e-PTFE vent membrane and designed (aluminum alloy/stainless steel/PBT/PC/PA6, etc.) material (Lower Cover) , components made by thermal fusion, ultrasonic welding (for plastic) or mechanical pressing (for metal vent valve), and then the PTFE porous material is protected by the upper cover, which can prevent it from being punctured, collided, etc. injury, increased lifespan, and product safety with reliability and durability. The entire component composed produces new functions and characteristics, reduces costs, and can realize one-click installation.

Typical features:

a.Excellent waterproof, breathable, hydrophobic and oleophobic

b.Easy to install

2.Characteristic

1).Fatures

a.Quickly equalize the pressure to prolong the service life, effectively manage condensation, and reduce the design complexity, weight and cost of the shell Waterproof and breathable components;

b.Provide reliable protection for sensitive electronic equipment from water and other liquids;

c.Effective shielding against pollutants, such as dirt, dust or salt;

d.Easy to install: fast and simple integration to ensure long-lasting performance in any application;

e.Safer: It adopts strong threaded structure and durable O-ring to reliably protect the waterproof and breathable products in the shell;

f.Reliable protection: SST Porous® Tech. Vent membrane can prevent dirt from entering even if it is immersed in water;

g.Rugged and durable: specially designed for chemical resistance, UV resistance, temperature resistance and hydrolytic stability;

h.Product quality: 100% quality control is adopted, in addition, all waterproof vent products with thread size M6 and M12 have full traceability;

3.Application

1).Automobile

a.Motors and pumps

b. ECU

c. SCR

d.Battery pack

e.Sensors

f.powertrain

2). Electronic equipment

a.Air quality sensor

b.Outdoor lighting

c.Telecommunications equipment

d.Outdoor Electronics

Ⅲ、Snap-in vent valve

1.Overview

The SST-Porous® plastic snap-in vent valve product is independently developed by SST. It is composed of SST-Porous® PTFE vent membrane and PBT plastic injection molded parts, which are welded by hot melt or ultrasonic, and covered by the PBT cover Protecting the PTFE porous material can prevent it from being punctured, collided and other injuries, improve the lifespan, and the safety, reliability and durability of the product. The entire component composed produces new functions and characteristics, reduces costs, and can realize one-click installation.

2. Fatures

a.Quickly equalize the pressure to prolong the service life, effectively manage condensation, and reduce the design complexity, weight and cost of the shell Waterproof and breathable components

b.Provide reliable protection for sensitive electronic equipment from water and other liquids

c.Effectively shield pollutants, such as dirt, dust or salt

d.Easy to install: quick and easy integration to ensure long-lasting performance in any application

e.Safer: the use of strong threaded structure and durable O-ring, so as to reliably protect the waterproof and breathable products in the shell

f.Reliable protection: SST Porous® Tech. Vent membrane can prevent dirt from entering even if it is immersed in water

g.Rugged and durable: high strength, resistant to harsh environments, specially designed for chemical resistance, UV resistance, temperature resistance and hydrolytic stability

h.Product Quality: Durable automotive-grade glass-filled PBT plastic with 100% quality control

i.The oil repellency level is as high as 8, AATCC 118-1992, and the hydrophobic vent meets the waterproof level up to IP69K

3.Application

1).Automobile

a.Motors and pumps

b. ECU

c. SCR

d.Battery pack

e.Sensors

f.powertrain

2). Electronic equipment

a.Air quality sensor

b.Outdoor lighting

c.Telecommunications equipment

d.Outdoor Electronics

Ⅳ、Adhesive vent membrane

1.Overview

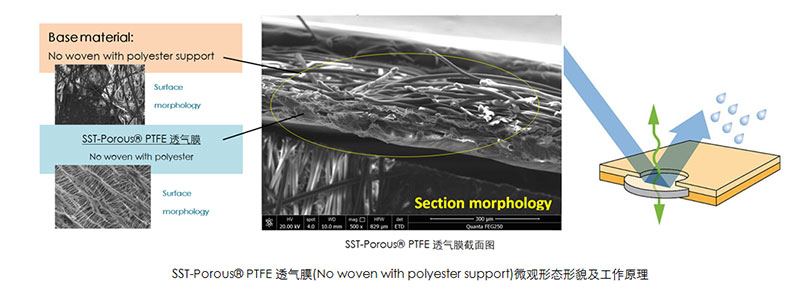

SST-Porous® adhesive vent membrane is independently developed by SST. It is composed of SST-Porous® PTFE breathable membrane and polyester or nylon fabric substrate through a special composite process. The formed SST-Porous® adhesive vent membrane still maintains a high air flow rate and average pore size, and is not easy to delaminate. Colors are available in lake blue and black.

SST-Porous® adhesive series vent membranes are combined with acrylic double-sided adhesive tape through precision processing to form adhesive vent membrane products.

SST-Porous® adhesive series vent membrane has the functions of waterproof, breathable, dustproof, and balancing the pressure difference inside and outside the shell (pressure compensation), and can be fixed to the surface of the electronic component shell by automatic or manual methods.

The SST-Porous® PTFE vent membrane is die-cut with adhesive through the precision die-cutting process according to the customer’s actual working conditions or specifications, and made into a customized waterproof and breathable product normally shipped by SST.

2. Fatures

a.Extend the service life of electronic equipment products, and quickly achieve pressure equalization to reduce the stress on the sealing ring of the equipment housing

b.Reliable protection, the hydrophobic and oleophobic properties provided by the SST-Porous® PTFE vent membrane enable the product to block the entry of water, salt, corrosive liquids and particles

c.Can improve durability, by following industry standards to increase the durability of sealed enclosures

d.Flexible design makes installation and maintenance more convenient

e.A wide range of products, with high air flow, high temperature stability, and waterproof and breathable products with strong adhesive for the surface of the shell

f.Outstanding technical expertise, rich professional technical knowledge accumulated by SST engineering department, providing the most professional technical service and support for global terminal applications

3.Application

1).Automobile

a.Car headlights

b.Car tail lights

c.Car fog lights

d.Car signal light

2). Electronic equipment

a.Gas electrochemical senso

b.Pressure Sensor

c.Sweeping robot

Ⅴ、Welded vent membrane

1.Overview

SST-Porous® welded BD01 series vent membrane is independently developed by SST. It is composed of SST-Porous® PTFE vent membrane and polyester non-woven fabric substrate, through hot pressing lamination equipment, at specific temperature, pressure and speed Next to paste. The formed SST-Porous® BD01 series vent membrane still maintains a high air flow rate and average pore size, and is not easy to delaminate.

SST-Porous® BD01 series vent membrane can be directly welded with certain types of plastic shells (PP, PBT, ABS, PC, PA6, etc.) by ultrasonic or thermal fusion.

SST-Porous® welded BD01 series vent membrane has the functions of waterproof, breathable, dustproof, and balancing the pressure difference inside and outside the shell (pressure compensation), and can be fixed to the surface of the electronic component shell by automatic or manual methods.

2.Characteristic

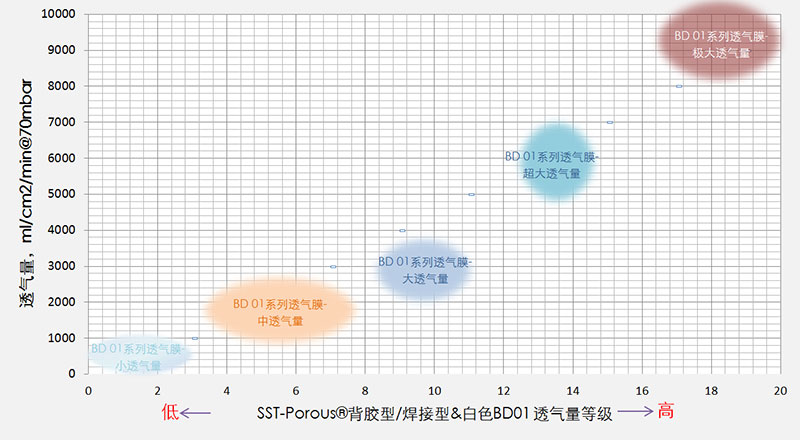

1).Breathability

SST-Porous® welded BD01 series vent membrane is made of SST-Porous® vent membrane and polyester non-woven fabric (non-woven fabric) through hot pressing, which has excellent air permeability.

|

|

BD 01 series vent membrane – low air permeability |

BD 01 series vent membrane – medium permeability |

BD 01 series vent membrane – high breathability |

BD 01 series vent membrane – super breathable capacity |

|

Typical Airflow |

> 500 |

1000~2000 |

2500~3000 |

Over 5000 |

|

Notice: ※ The air permeability test is the size of the air permeability before use, in ml/min/cm2 ※ Test pressure difference,at ΔP = 70 mbar, RT |

||||

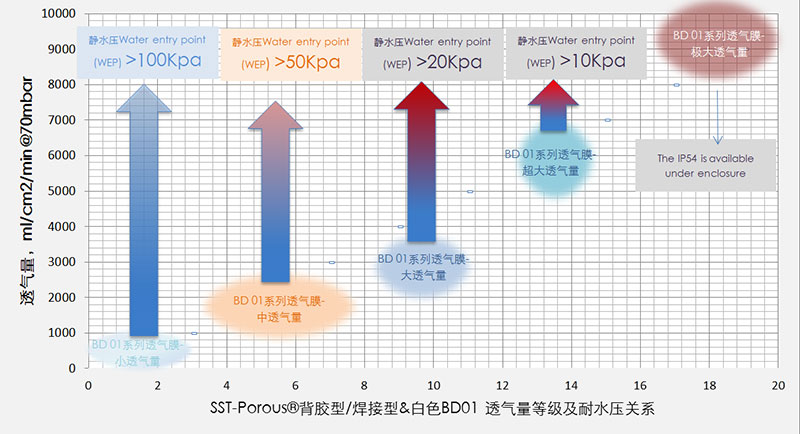

2).Water resistance

In the structure of the SST-Porous® welded BD01 series venting membrane, the SST-Porous® venting membrane has a network structure composed of “fibers” and “nodes”, which not only has excellent ventilation effect, but also has excellent waterproof effect .

| BD 01 series vent membrane – low air permeability | BD 01 series vent membrane – medium permeability | BD 01 series vent membrane – high breathability | BD 01 series vent membrane – super breathable capacity | |

| Water entry point (WEP) | > 100 | > 50 | > 20 | > 10 |

| IP protection level |

IP54、IP65/ IP66(depending on the installation structure)、IPX7、IPX8、IP69K |

IP54、IP65/ IP66(depending on the installation structure)、IPX7、IPX8、 | IP54、IP65/ IP66(depending on the installation structure)、IPX7 | IP54、IP65/ IP66(depending on the installation structure)、IPX7 |

|

Notice: ※ Test pressure difference,at ΔP = 70 mbar, RT,unit:kPa ※ Protection against foreign particles, water, and touching according to ISO 20653:2013 |

||||

3).Hydrophobic and oleophobic character

In order to meet different application requirements, SST-Porous® can provide water-blocking membrane (hydrophobic membrane), super water-blocking membrane (oleophobic membrane), and when facing low surface tension liquid, SST-Porous® welded BD01 series vent membrane can Satisfy the hydrophobic and oleophobic function in applications where there is a possibility of contact with oil stains.

※ BD 01 series Characteristics of vent membrane (Before Application):

Oleophobic character: according to AATCC 118

4).Weldable

The SST-Porous® welded BD01 series venting membrane can be fixed to the plastic shell by heat fusion or ultrasonic welding.

a. Common types of plastics that can be welded: ABS, PBT, PP, HDPE, PA6, PC, etc.

b. Selection of hot melt welding temperature

It mainly depends on the melting point (Tm) of the plastic, which is generally 30~50°C higher than the melting point of the selected plastic, and the welding can be carried out smoothly.

5).Firmly welded

The well-designed SST-Porous® welded BD01 series vent membrane takes into account the welding characteristics with different material surfaces, and has the characteristics of high welding fastness, safety and reliability.

Welding fastness performance

Adhesive strength according to FINAT FTM 1, RT Steel (after 0.5 h) :> 25N/25 mm

6).Wide temperature range

SST-Porous® welded BD01 series vent membrane, high and low temperature characteristics: -40 °C to +160 °C (when welding)

illustrate:

1) The use temperature of the product mainly depends on the final use temperature of the double-sided adhesive tape or the base material of vent membrane;

2) For specific temperature requirements, SST application engineers can provide adhesive vent membrane products with a wider temperature range

7).Not PFOA

SST-Porous® welded BD01 series vent membrane, the material used is different from the PTFE raw material used in e-PTFE. It is obtained from the suspension and does not require emulsifier-perfluorooctanoic acid (PFOA) (PFOA is used Suspected of being carcinogenic). Therefore, SST-Porous® welded BD01 series vent membrane does not contain PFOA harmful substances.

For the specially designated SST-Porous® welded BD01 series vent membrane, PTFE dispersion raw materials prepared by environmentally friendly emulsifiers can be selected, so that the SST-Porous® waterproof vent membrane does not contain PFOA.

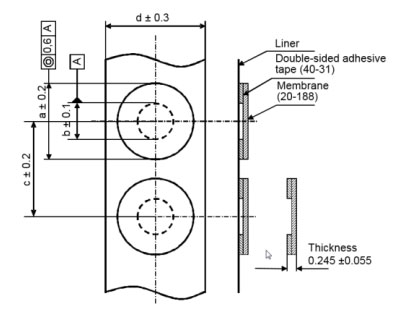

8).Customizability

SST-Porous® welded BD01 series vent membranes can choose different stacking methods, different specifications and sizes or appearance shapes according to customer needs.

|

※The outer diameter (OD) and inner diameter (0) of the breathable film can be selected Outer diameter (OD) size: 0mm Inner diameter (ID) size: 1-28 mm Notice: SST can finally determine welded vent membrane products of different shapes or specifications according to the customer’s drawings or ideas |

3.Application

a.Automotive – Lamps, Electronics, Fluid Tanks, Motors

b.Light Enclosures – Industrial, Outdoor, Stage and Event Lighting

c.Sensors – Humidity Sensors, Temperature Sensors, Pressure Sensors and Gas Sensors

d.Protective case

e.Universal housing

f.Electrical and communication junction boxes/outdoor enclosures

g.Solar housing

h.Electrical appliances