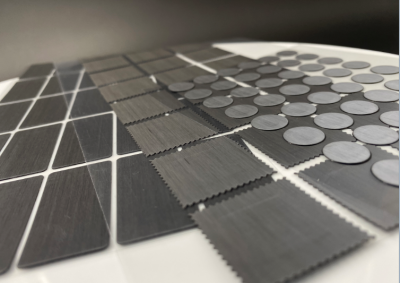

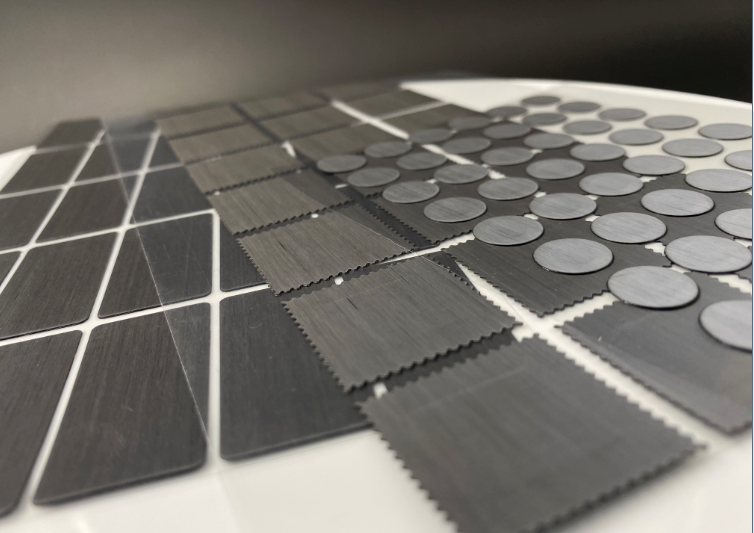

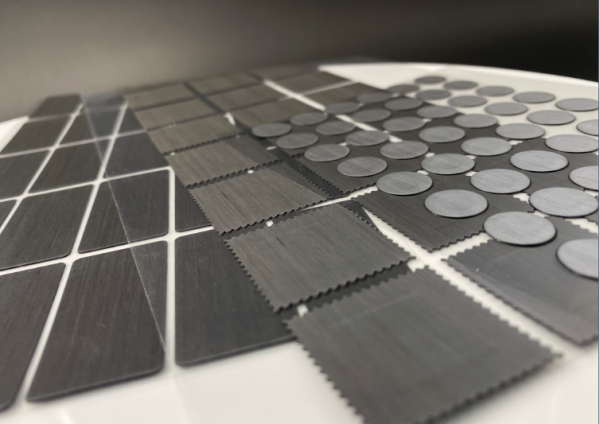

SST-Porous® Adhesive eptfe membrane vents BD G00 series — (typical application: Headlamp, Tail lamp,Turn signal lamp, Reflector,Battery,Security device,Distribution box, Electric machinery etc)

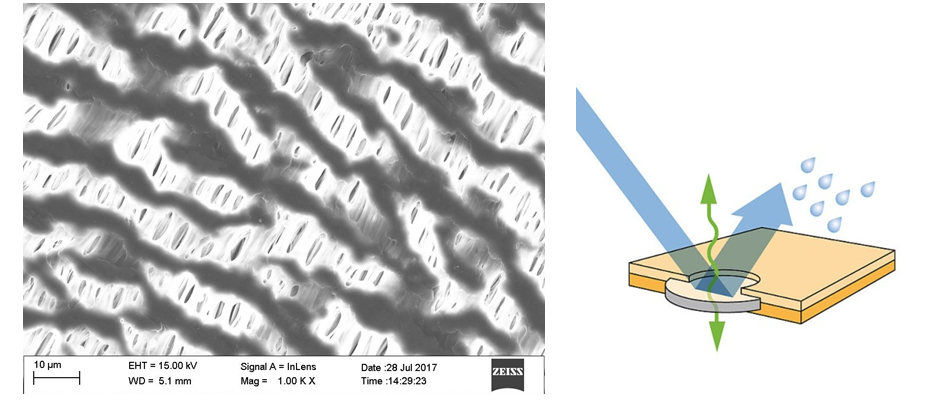

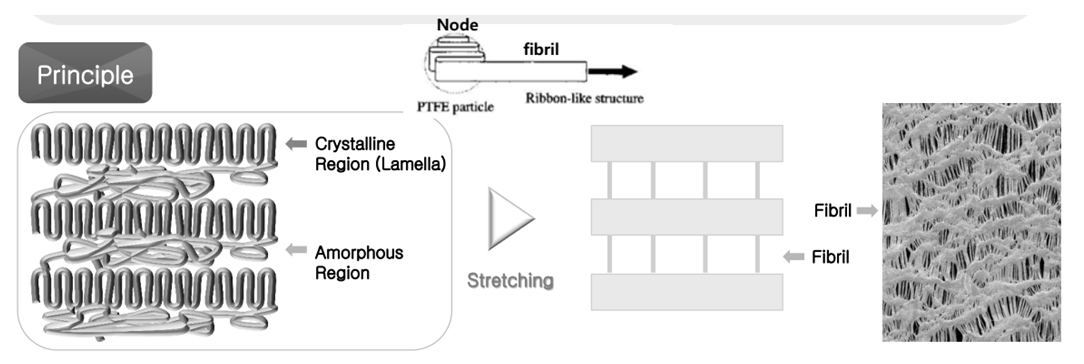

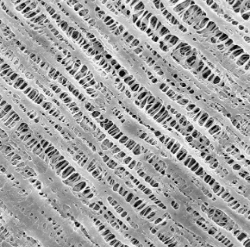

SST-Porous®BD G00 series ePTFE membrane vents in grey color, made by over 95% PTFE fine powder and some extend of black color, through special stretching process, thousands of “nodes” and “fibers” are formed.

As its proprietary ePTFE microporous membranes allow air and gases to pass through freely, so moisture can diffuse before condensation problems arising.

What is SST-Porous® Adhesive & BD G00 series Waterproof venting?

SST-Porous® BD G00 series–Adhesive ePTFE protection vents in Gray color , research & developed by Spider(SST) independently. made by 100% PTFE material, combined with acrylic adhesive by precise processing to form an adhesive breathable protection vents.

Its main typical applications include car lights, shared bicycle batteries, distribution boxes, motors, security equipment, etc

SST-Porous®BD G00 series– adhesive protection vents in gray color, they could reliably keep out rain, sleet, snow, dust, dirt and debris, and continuously equalize internal pressure(compensate pressure). They could be mounted to the surface of the electronic component housing either automatically or manually.

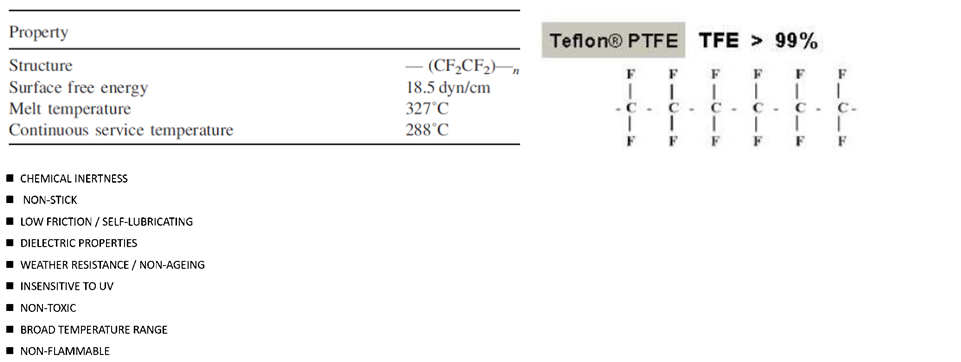

What is PTFE membrane?

SST-Porous® Waterproof & air permeable membrane

-

SST-Porous® ePTFE waterproof & air permeable membrane(stretching process)

By a special two-way stretchingg , the aggregation structure area of PTFE raw material was stretched to form ”fiber”, and the unstretched area formed “node”, thus the spidery porous PTFE material comes.

-

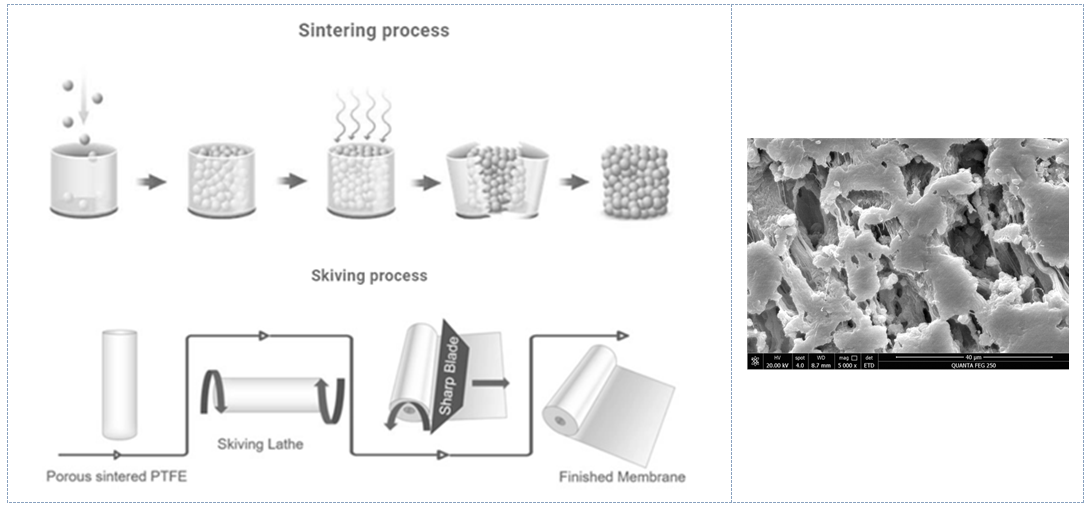

SST-Porous® s-PTFE waterproof&air permeable membrane(sintering process)

By means of powder metallurgy, PTFE powder will change to porous PTFE material in the form of flake or component through molding, sintering and skiving process.

-

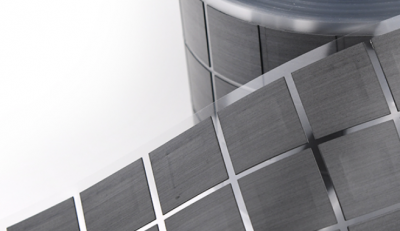

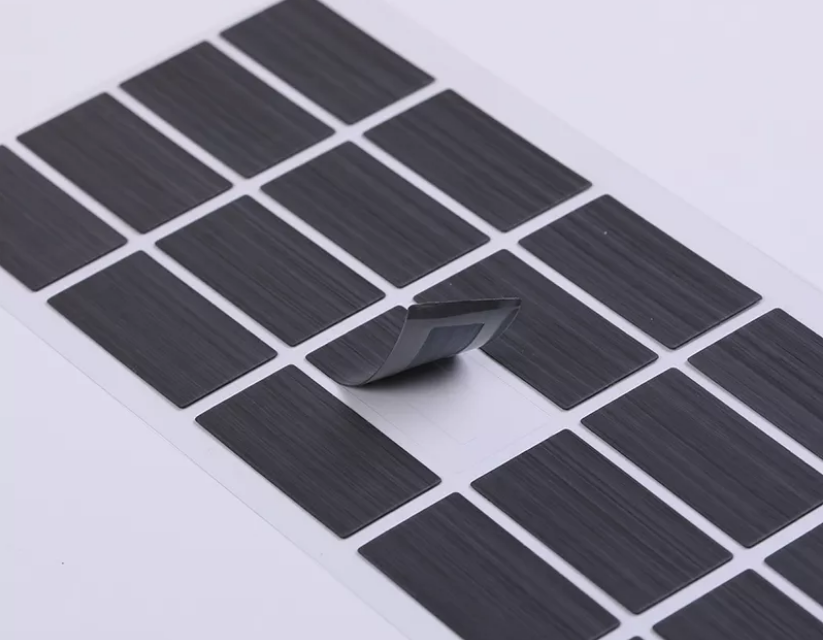

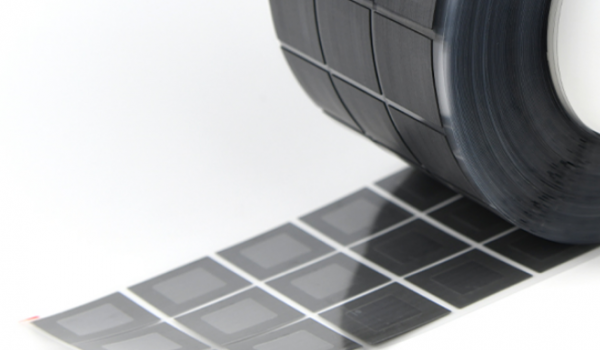

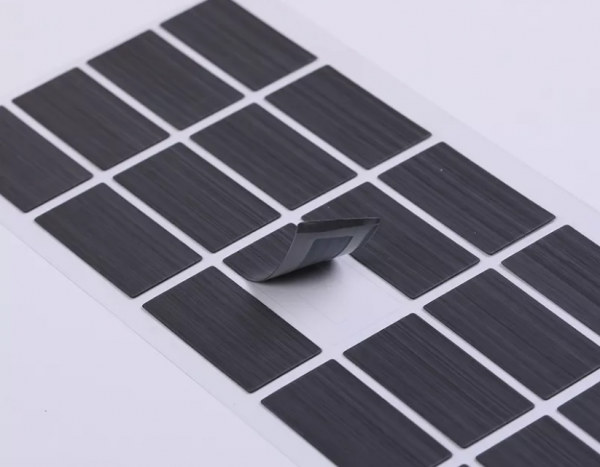

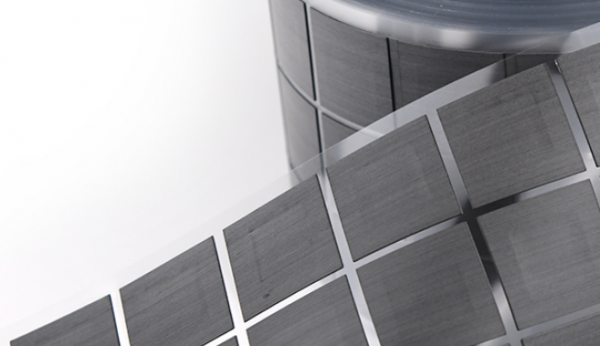

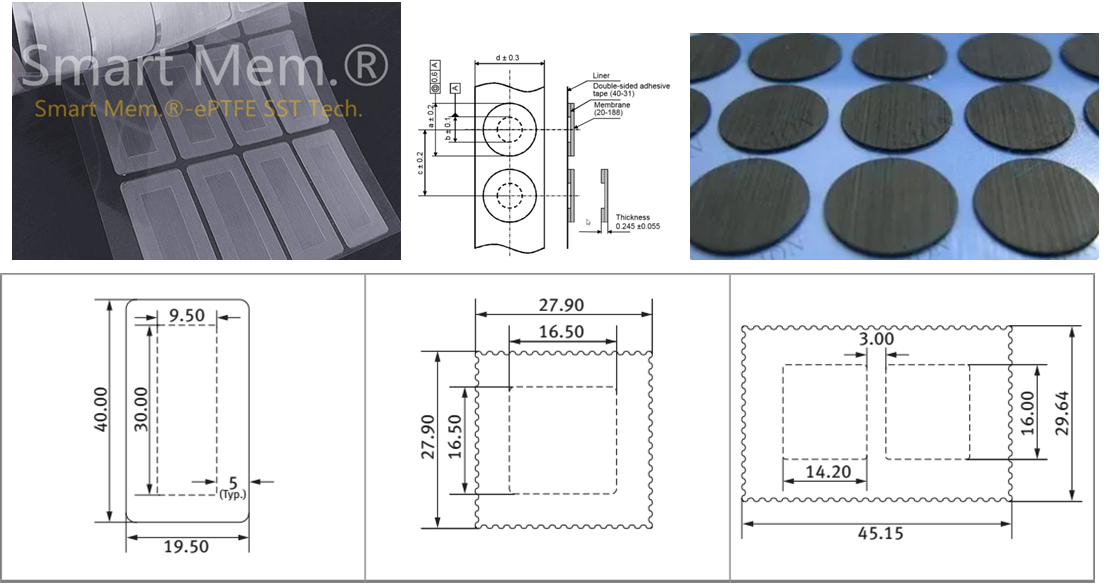

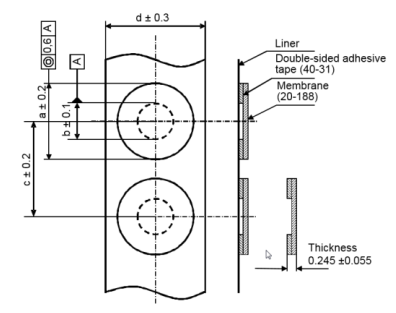

SST-Porous®Adhesive & BD G00 series in grey color–precision die cutting process

By our precision die cutting process,BD G00 series could accept custom designed and sized venting products.

Physical Characteristics:

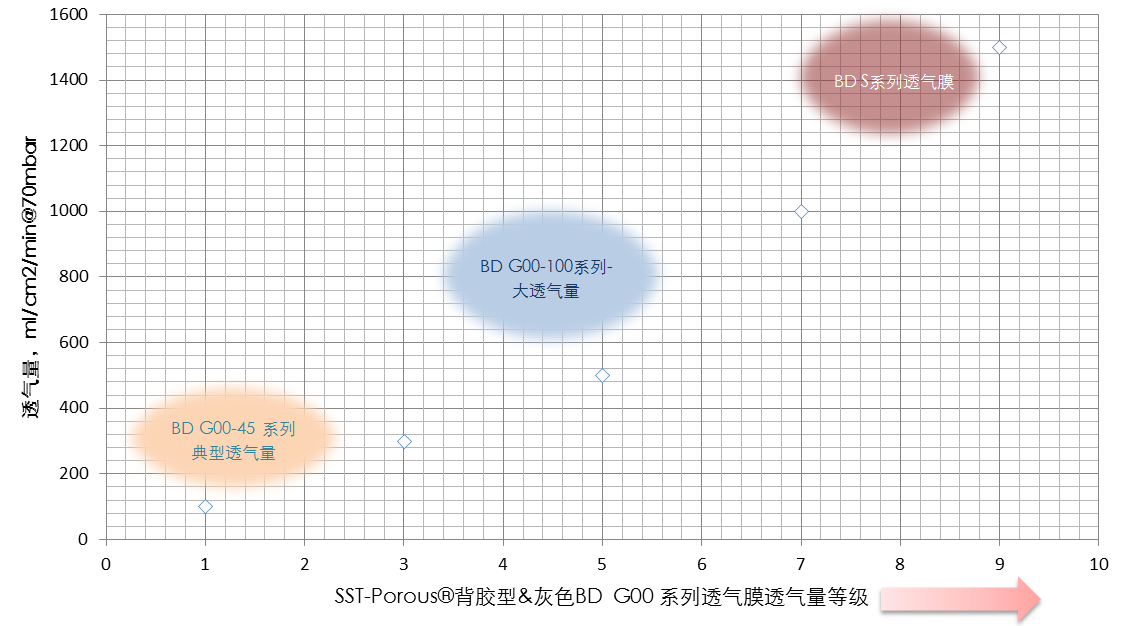

1. Air permeability

SST-Porous® BD G00 adhesive series ePTFE membrane, having grey or black color available, combined with acrylic adhesive then formed to air permeable vents with excellent airflow.

BD G00 series characteristic (Before Application):

Typical Airflow: > 400 ml/min/cm2(at ΔP = 70 mbar, RT)

Attention:

SST-Porous® sPTFE waterproof & breathable membrane, serial number named BD S00

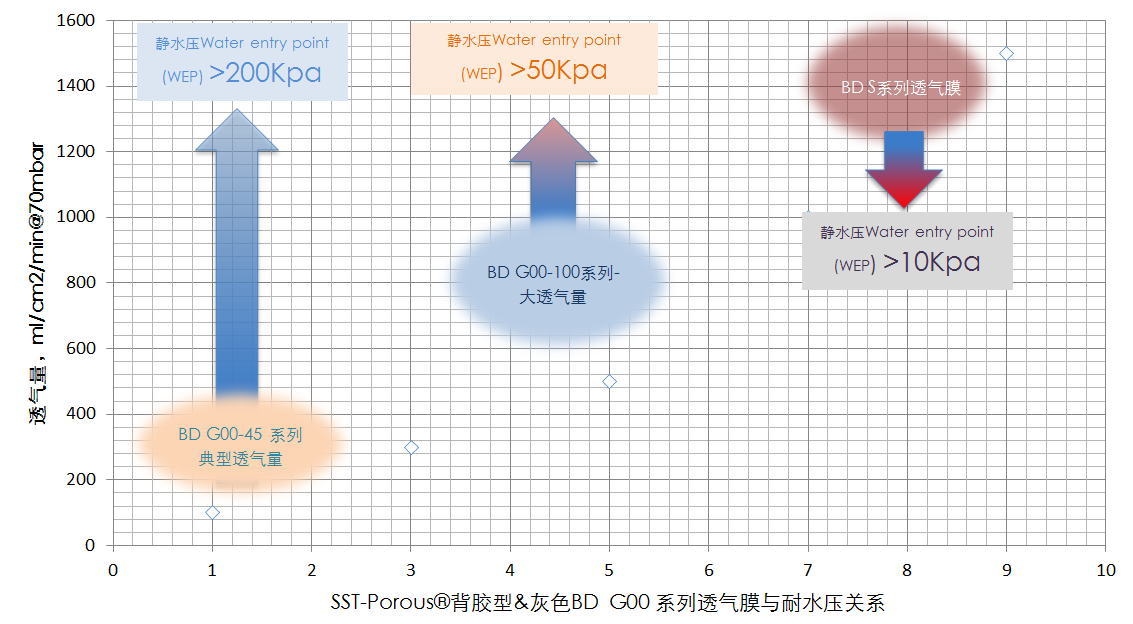

2. Water resistant

SST-Porous® BD G00 serial–adhesive vents protection, due to the composition of “fiber” and “node” network structure, the vents not only with excellent permeability performance but outstanding water resistant.

|

※ BD G00 series feature: (Before Application): ①Water entry point (WEP):> 50 kPa (Dynamic WEP 30 sec, RT) ②Ingress Protection(IP) rate: IP54、IP65/ IP66、IPX7、IPX8、IP69K (Protection against particles, water, and others according to ISO 20653:2013) |

3. Hydrophobic & oleophobic

SST-Porous® could supply hydrophobic and Oleophobic to meet different application requirement. As it’s Oleophobic characteristic, the protective vent could maintaining airflow even after contact with high-viscous or low surface-tension liquids.

※ BD G00 serial characteristic (Before Application):

Oleophobic rate from 1 to 8 (according to AATCC 118)

4 Weldability

SST-Porous®BD G00 series(no adhesive), The breathable membrane could be mounted on the plastic housing by means of thermal melt or ultrasonic welding.

-

Common type of plastic that could be welded

ABS,PBT,PP,HDPE,PA6,PC etc.

- Temperature of thermal welding

The temperature mainly depends on the melting point (Tm) of the plastic, generally 30~50℃ higher than selected plastic TM can be smoothly welded.

5 High adhesive strength

SST-Porous®BD Goo series Adhesive venting in grey color, the designed double-sided adhesive, in addition to its good adhesive with low surface enery of PTFE , but also take into account the viscosity of the surface with different materials.

※ Adhesion Properties of Adhesive

Adhesive strength according to FINAT FTM 1, RT Steel (after 24 h) : > 19 N/25 mm

6 Withstanding low and high temperature

Continuous Operating Temperature Range: -40 °C to +130 °C (when adhered)

Explanation:

- the venting usage temperature mainly depends on the temperature of adhesive or the venting base material;

- if special temperature required, SST could supply adhesive venting with more wider range of temeprature.

7 None-PFOA

SST-Porous®BD S00 serial, adhesive venting in white color, the membrane used is ePTFE material different from PTFE material, it’s obtained from suspension liquid, no need emulgator PFOA (PFOA suspected having carcinogenic effects), so BD S00 serials dont have PFOA.

And,if specified SST-Porous® BD G00 series Adhesive vent , we could choose eco-friendly emulgator prepared by PTFE dispersion raw materials, thus, SST-Porous® waterproof and breathable membranes do not contain PFOA.

8 Customizability

SST-Porous®BD G00 series Adhesive vent, the double-sided adhesive composition, package method, size, and shape could be customized.

|

※Venting size OD &ID option OD size: 2~30 mm ID size: 1~28 mm Attention: SST could produce the adhesive venting according to customer drawing or sample. |

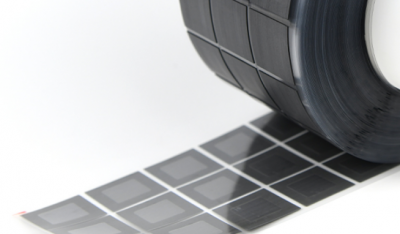

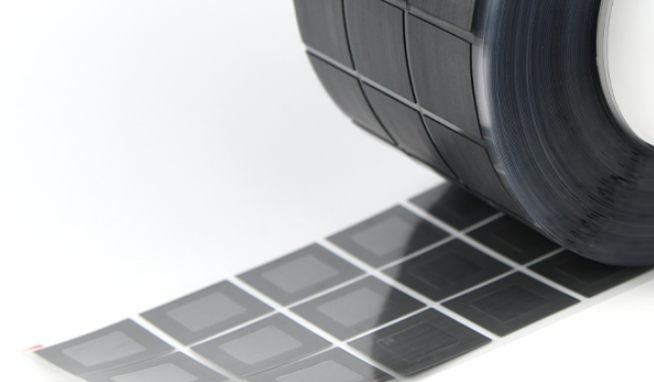

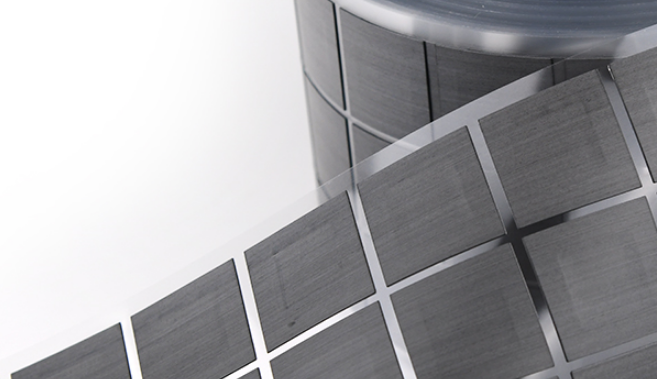

※Supply Mode

|

Supply Mode |

Description |

|

By sheet |

50~150pcs/sheet |

| By roll in single row |

50~100m/roll |

| By roll in multi-row |

50~100m/roll |

Typical Application

※ Heaplamp

※ Foglamp

※ Taillight

※ Emergency Brake Lamp

※ Automotive Electronics

※ Outdoolr Electronics

================================================================================

Handling / Installation guide

SST-Porous®BD G00 series Adhesive protection vents in grey color, it is a high-tech products that need professional final-processing.

Please contact us when planning to enter your manufacturing process, not all final-processings are compatible with this product. We will be pleased to offer our expertise in this field to you.

①Installation Surface

Recommended Surface roughness:Rz<10µm(max:Rz<16μm)。

Mounting surfaces should be dry and clean and free of oils, particles, release agent and other contaminants. the loose oxide layer on the surface will reduce the durability.

② Recommeded cleaning

Grease free solvent, like heptane, isp[ropanol or alcohol.

In case of incompatibility, select another cleaning agent for the application surface.

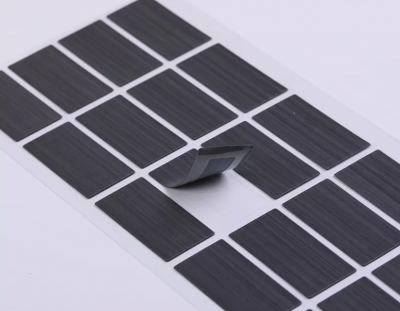

③Pressure sensitive adhesive operation guide

Press fit——suitable for semi-automatic installation

To achieve excellent press fit design and to obtain appropriate pressure,please follow the general recommendations as below:

- Pressing head shall be made by soft rubber of uniform thickness and at least 0 mm thickness(Shore hardness A 20 — 40 )

- The pressing head shall be vertical to the mounting surface and located in a position to apply pressure to the target/guard ring

- Accoding to the size of adhesive area, apply uniform pressure 7 bar recommended to the adhesive ring to seal device or housing. The pressure on the surface of the pressing head should be appropriate to avoid pressing into the venting area

- After pressing, the dwell time should exceed 5 seconds

- Allow at least 24 hours dwell time before using or testing the vent

- The above steps are very important to ensure the vent sealed on the housing firmly

Press fit——suitable for manual installation

- Ensure the entire adhesive ring is attached to the surface of the device or housing

- Apply light finger pressure to the adhesive ring at least two circles to assure the seal to the device or housing, be carefull not touch the central part of the vent

- Allow at least 24 hours dwell time before using or testing the vent

- The above steps are very important to ensure the vent sealed on the housing firmly

E-mail:weitaiyan@spider-amoy.com

WhatsApp:18695679892